Regulations

Machine Directive 2006/42/CE: a “Safe Approach” for the Systems

COBO offers a service from risk analysis to CE certification, working in team with the OEM to shorten certification times and costs.

Competence of system layout design and risk analysis evaluation

Our team can help OEM to build his own application risk analysis to start design with the right requirements, with a safety critical function identification.

System design

Once layout is defined, we can design the system to comply required safety level using our and third parts products.

Calculation of Performance level (according to En 13849-1)

We can perform the calculation of the right performance level of the safety part of the system, through:

-

-

-

components MTTF

-

diagnostic Coverage (DC)

-

common Cause Failures (CCF)

-

final PL calculation using standard algorithms

-

-

Software development (V-model, according to IEC 61508)

We can design software according to V-Model, necessary to get final certification according to IEC 61508. All our certified products have been designed according to this software architecture

Certification

At the end of the certification process, our team produces a signed document that the safety part analized is certified. On request, it is possible to get certification from external institutes (like TUV)

Consultancy

Our team can instruct customers to the safe approach for a system design, with specific training and consultancy

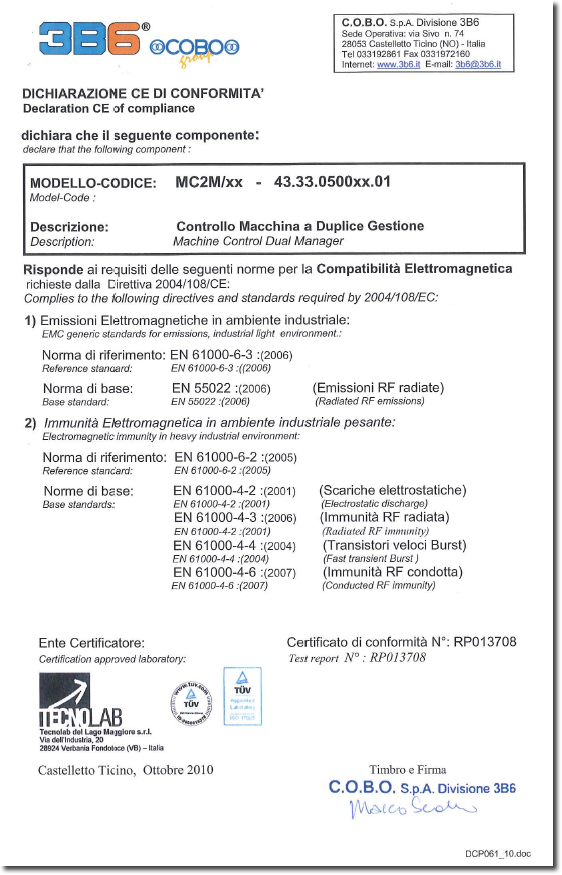

Full set of already certified products

COBO has produced many different products ready to use, already certified, in order to simplify the final certification process both if the product is used as stand-alone unit or inserted into a system.

Example of products lists:

| Product | Certification | Application |

| MC2M | SIL2, EN 13849 PL-D | Any mobile machine with hydraulic system. Firefighting vehicles, access platforms, cranes, excavators, etc |

| MIDAC+ | EN 13849 PL-D, SIL 2 (in progress) | Load limiting devices for cranes, excavators, agricultural vehicles, etc |

| LIBRA | EN 13849 PL-D | Cage leveling, generic leveling systems |

Case Studies

TELESCOPIC BOOM CRANE

System Certification: EN13849-PL C

Components: MIDAC+, Tera7, Mc2M, Joysticks, sensors, instrument cluster, cablings

Comments: in this architecture, the safety part (load limiter device) has certified sw inside a MIDAC+ controller, so any further crane modification or customization (not related to safety) does not require additional certificationsz

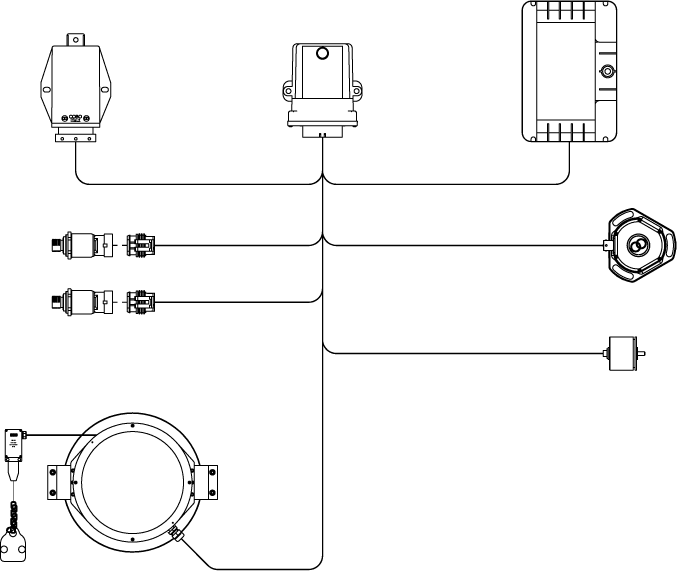

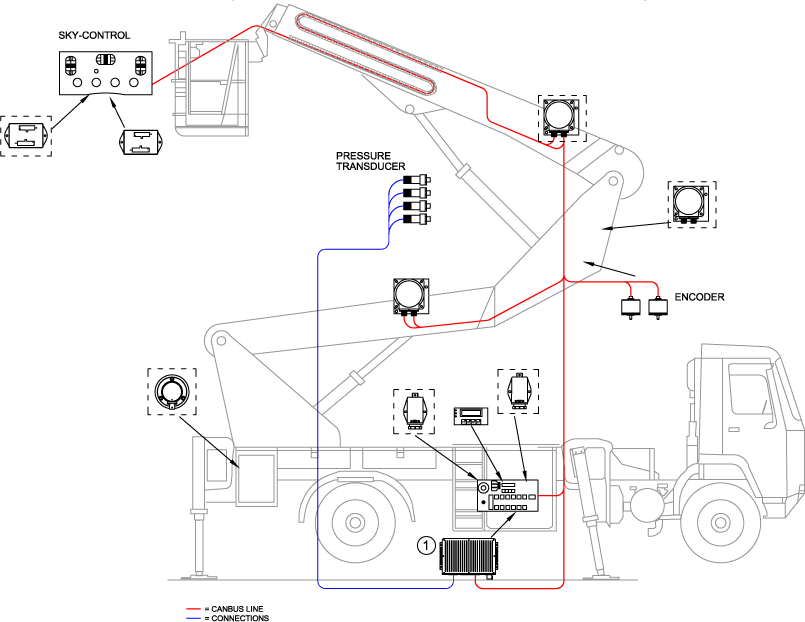

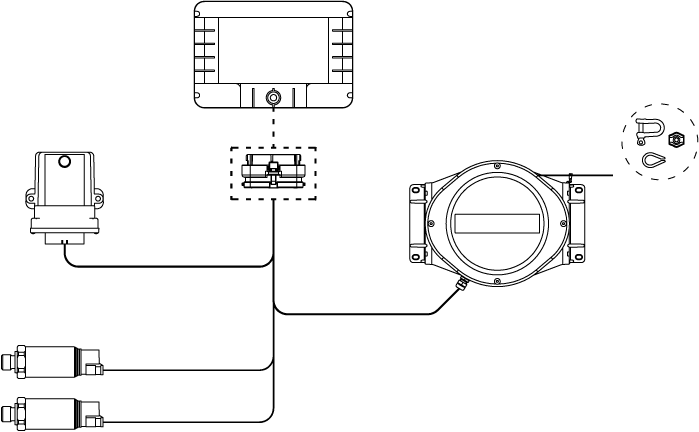

Access Platform

System Certification: EN13849-PL D

Components: Tera7, Mc2M, sensors, cablings

Comments: this architecture considers 2 MC2M both having LMI control software, to increase the PL necessary for this machine type

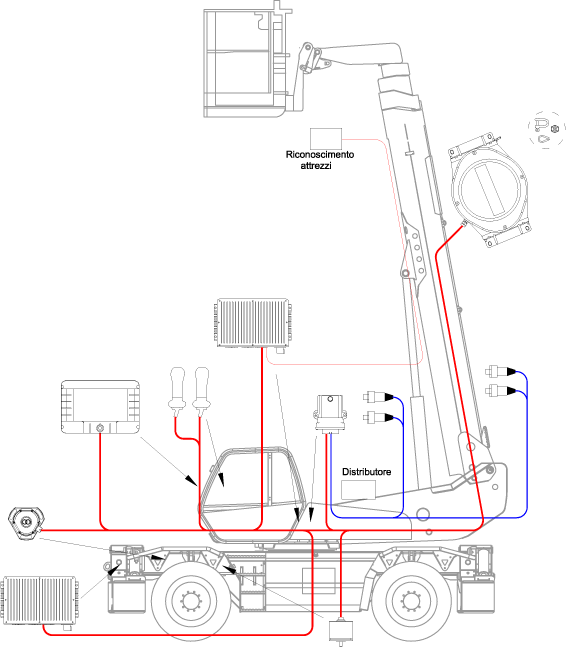

Telehandler (rotative)

System Certification: EN13849-PL D

Components: Tera7, 2xMc2M, MIDAC+, sensors

Comments: in this architecture, the safety part (load limiter device) has certified sw inside a MIDAC+ controller, so any further crane modification or customization (not related to safety) does not require additional certifications. Additional Mc2M ensure safety certification also for parts not related to load limiting control

Reachstackers

System Certification: EN13849-PL D

Components: MIDAC+, Tera7, Joysticks, sensors

Comments: in this architecture, the safety part (load limiter device) has certified sw inside a MIDAC+ controller, so any further crane modification or customization (not related to safety) does not require additional certifications