ISO-Bus turns into a databank

from "MAD" Magazine / March 2014

"Transparency and standardisation of ISO-Bus technology are among the priorities of AEF, the Agricultural Industry Electronics Foundation. Thus, the first database of certified functionality is born"

Are we sure that a tractor or machinery we intend to purchase feature ISO-Bus technology and relevant functions compatible with the technology we already have? Who should I contact if several operating units are not compatible? These are some crucial questions that AEF try to answer in order to facilitate the work of end-users and customer services, and as a consequence, of manufacturers. But first, let's briefly review (*) what AEF is. AEF stands for Agricultural Industry Electronics Foundation; it is an international independent group of manufacturers and associations related to agricultural mechanics and that actively foster the development and the ISO standardisation of electrical and electronic systems used in agriculture. Last November at Agritechnica, the international trade fair for agricultural machinery and equipment held in Hannover (Germany), AEF introduced two innovations: an ISO-Bus compliance certification plus the relevant identification label and the ISO-Bus Database.

AEF was founded at the end of 2008 by a small group of agricultural machinery manufacturers (John Deere, Cnh, Agco, Claas, Krone, Kverneland and Pöttinger) and two associations of manufacturers, the German Vdma (Verband Deutscher Maschinen und Anlagenbau) and the American Aem (Association of Equipment Manufacturers). Today AEF has 155 members including companies, associations and organizations.

AEF was founded at the end of 2008 by a small group of agricultural machinery manufacturers (John Deere, Cnh, Agco, Claas, Krone, Kverneland and Pöttinger) and two associations of manufacturers, the German Vdma (Verband Deutscher Maschinen und Anlagenbau) and the American Aem (Association of Equipment Manufacturers). Today AEF has 155 members including companies, associations and organizations.

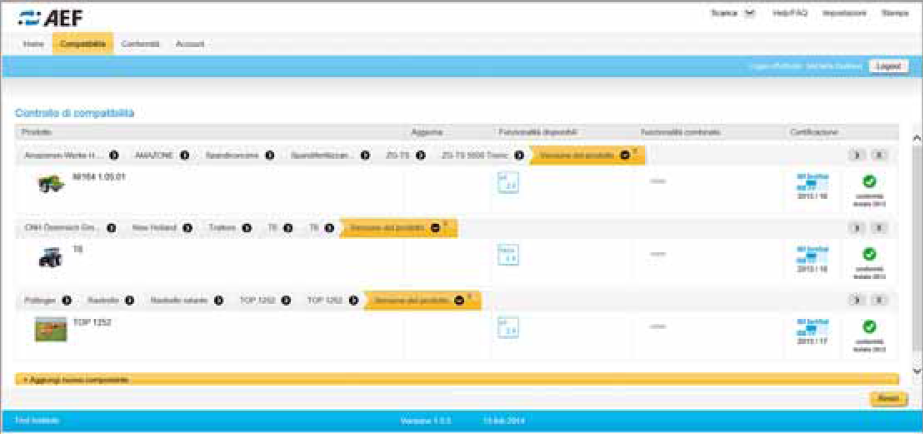

A screen of the AEF-ISO-Bus Database, the ISO-Bus function database of agricultural machinery and equipment. The portal will help all the actors in the agricultural sector, operators, dealers and manufacturers to identify and use the new international ISO-Bus standards.

A screen of the AEF-ISO-Bus Database, the ISO-Bus function database of agricultural machinery and equipment. The portal will help all the actors in the agricultural sector, operators, dealers and manufacturers to identify and use the new international ISO-Bus standards.

ISO-Bus in a nutshell

Electronics and software are an active part of modern agricultural machinery nowadays: safety, efficiency and precision are among the benefits deriving from their proper use. The ISO-Bus is the technology that allows you to communicate and exchange a series of electronic signals (information about position, data, functions, etc.) between the tractor, the operator and the control terminal, at the moment in which these are interconnected and used at work. The ISO-Bus technology also permits transferring and processing information gathered in other devices (smartphones and/or computers) for further data processing and management.

Certification: synonym of standardisation

Based on the rules of standardization established at international level for agricultural and forestry machine on the serial data network for control and communication (ISO 11783), AEF has established the guidelines that several manufacturers must follow regarding the creation and design of ISO-Bus technology in order obtain electronic units (terminals, tablets, control units, software) and electrical components compatible with one another. AEF has widened the standardisation protocol to the new functions that are added every year to modern agricultural machinery, introducing a new adhesive label to be affixed onto machines to certify their ISO-Bus compatibility and their functions. The certification is carried out and released by independent centres selected by AEF. Worldwide, there are only four authorised laboratories: two in Germany- IsoBus Test Center and Dlg Test Center Technology and farm-, one in the United States- the Nebraska Tractor Test Laboratory (NTTL)-, and one in Italy- Reggio Emilia Innovazione (REI) (www.reinnova.it). The Italian lab also coordinates the activities of IdeAgri (www.ideagri.net), a network of Italian companies between part and machinery manufacturers (current nine members: Actia, Ama, Arag, Argo Tractors, Comer Industries, Cobo Group, RE: Lab, Salvarani and Walvoil) that unite their resources and expertise to develop ISO-Bus applications and certified digital electronic solutions to be applied to agricultural machinery.

The adhesive label affixed onto the ISO-Bus certified equipment by AEF. The ISO-Bus functions that the machine or equipment can offer are indicated in the nine boxes. Key to abbreviations: UT Universal terminal; AUX-N, AUX-O Auxiliary Control; TC-BAS Task Controller basic; TC-GEO Task Controller geo based; TC-SC Task Controller Section Control; TECU Basic Tractor ECU; TECU-A Advanced Tractor ECU; SQC Sequence Control; ISB-ISOBus Shortcut Button.

The adhesive label affixed onto the ISO-Bus certified equipment by AEF. The ISO-Bus functions that the machine or equipment can offer are indicated in the nine boxes. Key to abbreviations: UT Universal terminal; AUX-N, AUX-O Auxiliary Control; TC-BAS Task Controller basic; TC-GEO Task Controller geo based; TC-SC Task Controller Section Control; TECU Basic Tractor ECU; TECU-A Advanced Tractor ECU; SQC Sequence Control; ISB-ISOBus Shortcut Button.

AEF Database

All the information regarding the ISO-Bus certifications of a machine or device has been collected in an on-line databank, the AEF ISO-Bus Database (www.aef-isobus-database.org). Currently being implemented by AEF or directly by member manufacturers, the new service will permit operators to check whether the combination of equipment (e.g. tractor-machinery) selected are compatible and which function can be actually viewed and managed. If a machine is not in the Database means it is not certified. The information contained in the ISO-Bus database will also be useful for dealers' service centres since problems can be easily identified through a more targeted diagnosis or, if this is not possible, dealers can send a "ticket" (electronic message) to the manufacturer, who will supply proper support. Once all the problems are identified and the solutions found, everything will be saved to the database which will be continuously updated.

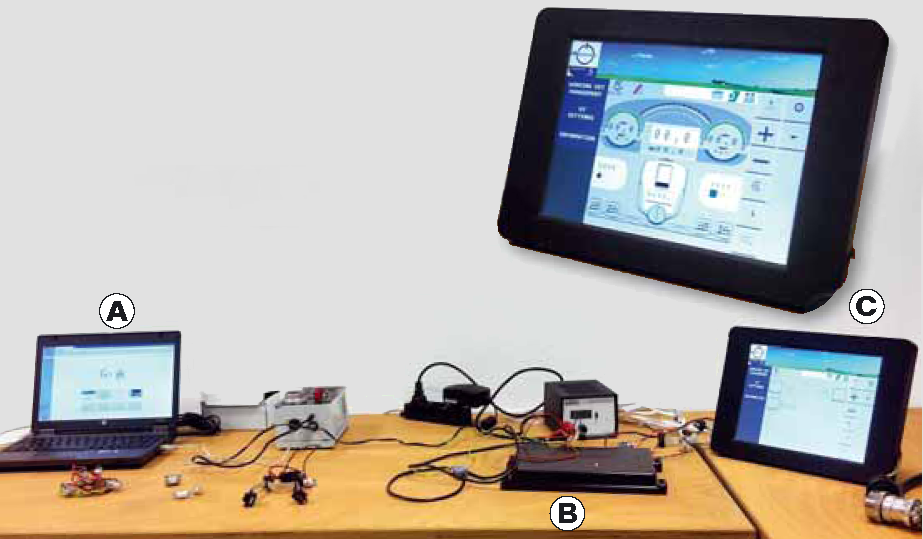

Reggio Emilia Innovazione (REI) is one of the four laboratories worldwide accredited by AEF to provide ISO-Bus certification. It also validates and guarantees conformity of machinery, components and equipment to ISO 11783 under a test bench by REI. In the picture: computer with AEF tool for compliance test (A); Arag control unit for a spraying machine (B); COBO Virtual Terminal (C) where the operator-controlled parameters are indicated (pressure, remaining litres, nozzles activation).

Reggio Emilia Innovazione (REI) is one of the four laboratories worldwide accredited by AEF to provide ISO-Bus certification. It also validates and guarantees conformity of machinery, components and equipment to ISO 11783 under a test bench by REI. In the picture: computer with AEF tool for compliance test (A); Arag control unit for a spraying machine (B); COBO Virtual Terminal (C) where the operator-controlled parameters are indicated (pressure, remaining litres, nozzles activation).

Alberto Caroleo